先决条件——ERP系统的演变

1.物料需求计划(MRP):

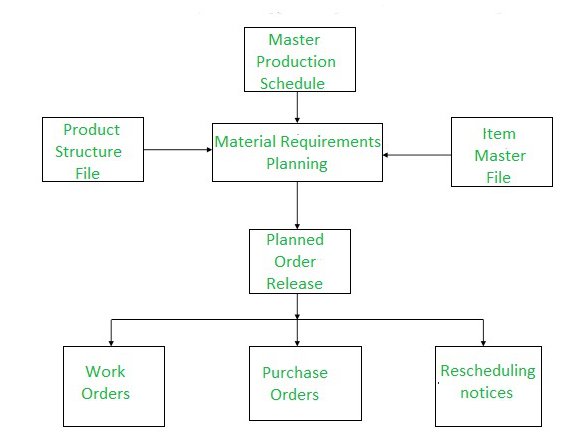

开发于 1970 年代,任何组织需要时都会管理原材料,即公司需要哪些材料存储在数据库中。此外,它讲述了任何材料的短缺。物料需求计划是工业中广泛使用的生产计划和调度方法。

MRP 的函数是提供物料可用性,即用于按时生产所需数量。此过程涉及监控库存和需求,从而自动创建采购或生产采购建议。 MRP 的主要目标是确定需要哪种材料、所需数量以及何时需要。它是因素材料库存和强调实物资产。

2.制造资源计划(MRP II):

制造资源计划于 1980 年代开发,是用于管理整个制造公司的闭环 MRP 的扩展。该系统提供了对所有职能领域都有用的信息,并鼓励跨职能互动。在这种情况下,属于制造单元的任务是自动化的或相关联的,以便最终增加产量。

它通过提供和订单承诺能力来支持销售和营销。它是一个基础广泛的资源协调系统,涉及公司其他领域的规划过程,如营销、财务和人力资源。

MRP和MRP II的区别:

| MRP | MRP II |

|---|---|

| Stands for Material Requirements Planning. | Stands for Manufacturing Resource Planning. |

| Developed in 1970s. | Developed in 1980s. |

| Widely used approach for production planning and scheduling in industry. | Provides an information that is useful to all functional areas and encourages cross-functional interactions. |

| Aims at releasing and managing manufacturing orders and purchasing requisitions. | Aims to control relevant material flows and production capacity while also taking into account the relationship between these material flows and the required capacity. |

| MRP is simply about ensuring the materials which are available to manufacture a specific part in a specific volume. | It take care of all other aspects of a job including ordering, tracking inventory and ensuring capacity. |

| It takes inputs all in order to make sure you have the right amount of materials/labor/machinery on hand at any given time to satisfy the market or your company production goals. | MRP II uses additional data from accounting records and sales for further analysis and forecasting of manufacturing requirements. |